Sure, in this form it is useless, but because the text and the geo is side by side, one can hand-edit it visually. Now in Bobby, just click cut-chain, and voila! the toolpath geometry is turned into a properly formatted G-code. I still drew the part in ACAD, I still created the exact toolpath in ACAD, but then instead of the LISP nightmare, export the DXF to BobCAD containing ONLY Well, needless to say that got very old very quick.

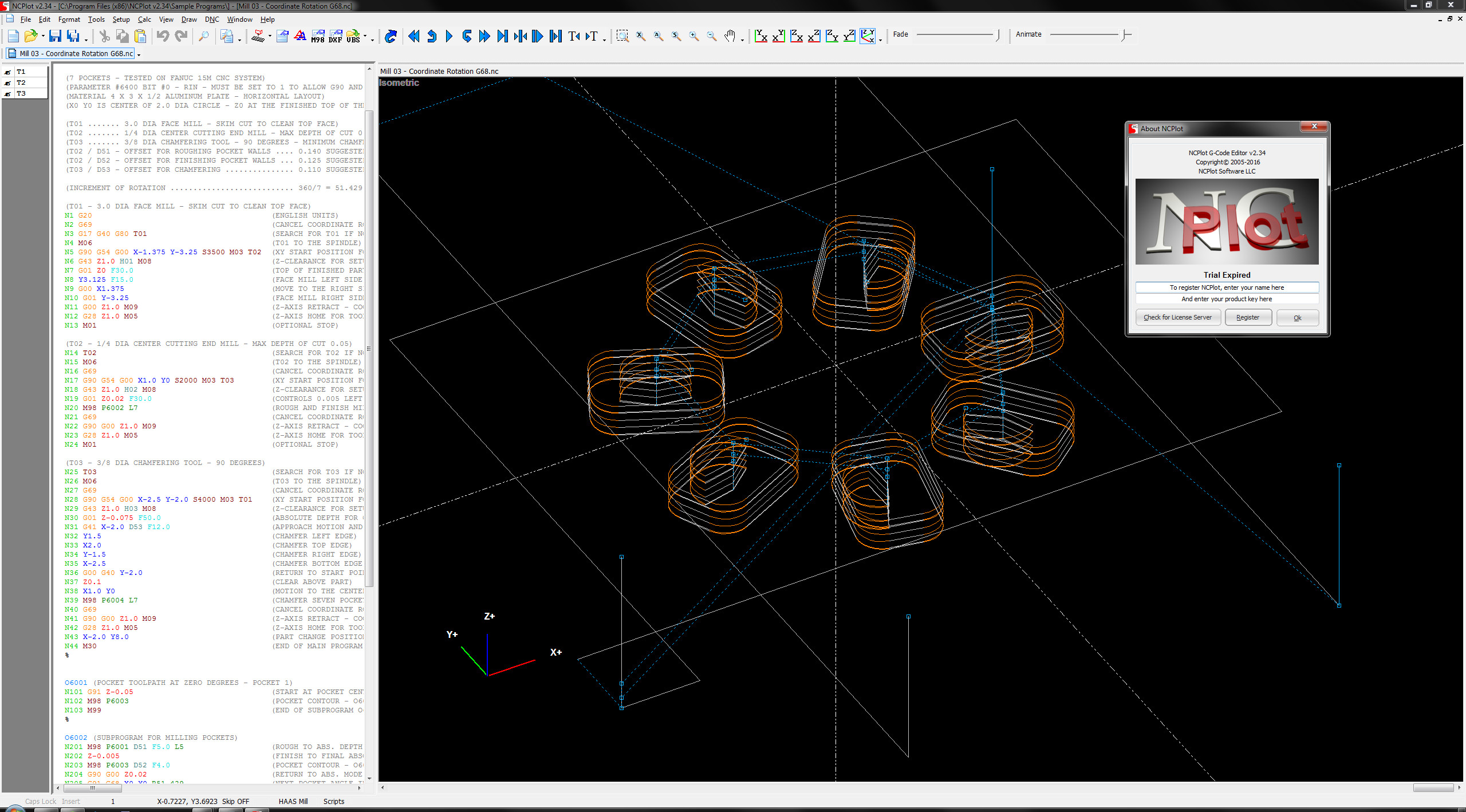

That seems like a very peculiar workflow.Actually Gregor, while it may seem like an odd way of doing things, it is kind of the point of the thread.įirst, the AutoCAD DXF to BobCAD route is simply due to the fact that back then that's all I could afford.ĭraw the part in ACAD, draw the exact toolpath I want the wire to follow, then a LISP routine spits out the coordinates into a text file, then manually edit the result in a blind. Seymour, I know it's not the point of your post at all, but I can't help wondering why: If you are not familiar with anything NcPlot has to offer but looking for a solution a problem you may or may not have, check out. In any case, if you are familiar with NcPlot, please go back and check out SketchNC and report back either here or on the NcPlot forum.

NCPLOT BUSINESS CODE

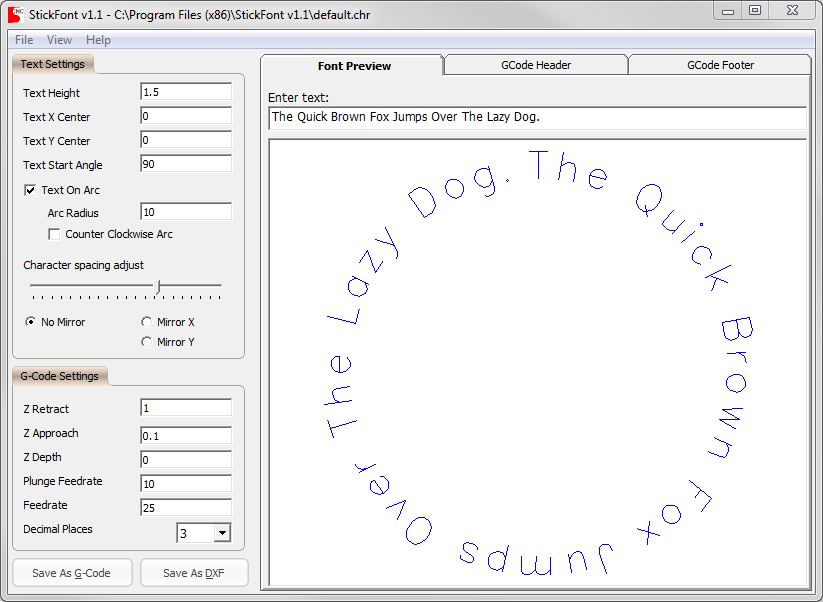

With a little attention from Scott, SketchNC could become one of the fastest tool to create 2D code for either 2 axis lathes, mills, WEDM, waterjet, laser, or. I have re-written a Wire EDM program using the new SketchNC, manually edited it, verified it using NcPlot, and then ran it on a production part. I use NC-Plot to verify, check or edit all of the programs written for all of the above machines. ( see above, but note that BobCAD is now DEFUNCT ) I write ALL of my Wire EDM programs using solid model to DWG, and then AutoCAD and Bobcad V21. I write ALL my lathe programs using solid model to DWG, and then AutoCAD and Bobcad V21. ( ACAD is a given from the maintenance, BobCAD V21 is now defunct ) I write the oddball Mill programs using solid model to DWG, and then AutoCAD and BobCAD V21. ( active permanent maintenance on Inventor and FeatureCAM ) I write most of my Mill programs from a solid model using FeatureCAM. It is NOT ALL THAT FAR AWAY from being able to provide a typewriting CAM solution for someone with G-code and machining knowledge!

NCPLOT BUSINESS UPDATE

The original ( v.1.00.00) was barely (if even that) good enough to hint at where he's trying to go, but the update is definitely a a huge step!ĭoes it ( in it's current form ) work for those on a shoestring budget? Nope, not by a shot. There is an update to his efforts as of 06/05/19, and SketchNC is now at v.1.00.19 In my view it wasn't even ready for an Alpha back then, let alone Beta.

NCPLOT BUSINESS SOFTWARE

It is about another piece of software NCPlot ( aka Scott Martinez, aka metlhead ) is working on, which is SketchNC.

NCPLOT BUSINESS FREE

If you are not, then feel free to ask when and how. If you are a user, there is no need to explain.

It has been a life saver in a shit ton of cases. Just like some of the forum members here, I am a very very happy and satisfied user of NC-Plot. OK, so just as the title says, I am taking the liberty of trying to shine a light onto a not-so mainstream machining related product: NC-Plot/SketchNC

0 kommentar(er)

0 kommentar(er)